เหตุใดการเลือกกระดาษจึงสำคัญต่อการออกแบบพระคัมภีร์แบบปรับแต่ง

บทบาทของกระดาษต่อการอ่านได้ชัดเจน ความทนทาน และการใช้งานระยะยาวของพระคัมภีร์แบบปรับแต่ง

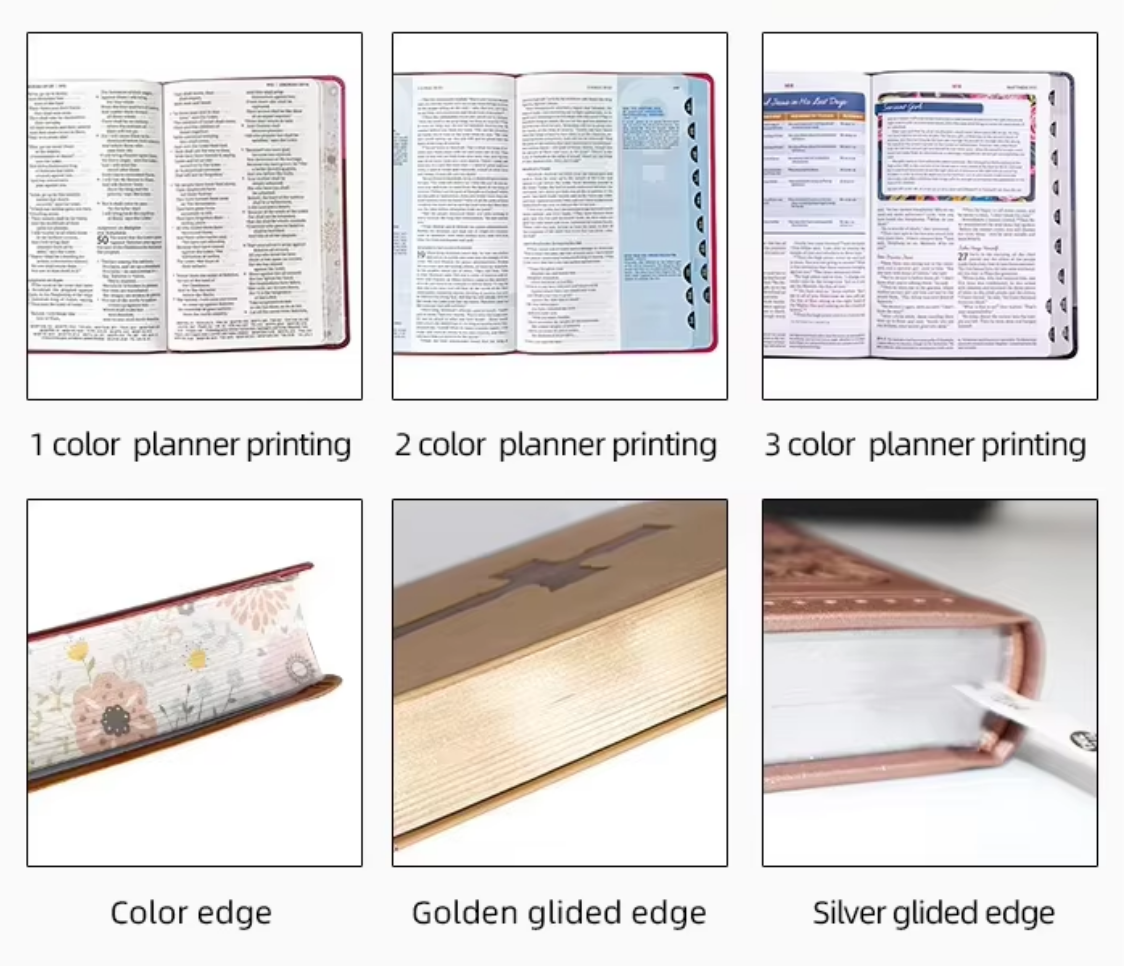

ประเภทของกระดาษที่ใช้มีความสำคัญอย่างยิ่งต่อความทนทานของพระคัมภีร์ที่ออกแบบพิเศษเมื่อใช้งานเป็นประจำในระยะยาว ส่วนใหญ่ผู้คนนิยมใช้กระดาษที่บางแต่แข็งแรงประมาณ 28 ถึง 36 กรัมต่อตารางเมตร ซึ่งพกพาสะดวกและไม่ฉีกขาดง่าย กระดาษควรจะมีความทึบแสงสูงด้วย โดย ideally ควรเกิน 94% เพื่อป้องกันตัวหนังสือทะลุผ่านมาด้านหลังจนทำให้อ่านยาก นอกจากนี้ เรารู้ดีว่าหากกระดาษมีกรดปนอยู่จะเกิดอะไรขึ้น จากการศึกษาล่าสุดของผู้เชี่ยวชาญด้านการอนุรักษ์ห้องสมุดพบว่า พระคัมภีร์ที่ผลิตจากกระดาษธรรมดาแทนที่จะใช้กระดาษชนิดปราศจากกรด จะเริ่มเสื่อมสภาพเร็วกว่าถึงสองเท่าในสภาพแวดล้อมที่ชื้น สำหรับการจัดพิมพ์ฉบับเพื่อการนมัสการ ผู้จัดพิมพ์ให้ความสำคัญอย่างมากกับพื้นผิวที่เรียบเนียน เพราะช่วยให้ตัวอักษรพิมพ์ออกมาชัดเจนไม่เลอะเลือน และควรระวังเรื่องปริมาณลิกนินด้วย กระดาษที่มีลิกนินมักจะเปลี่ยนเป็นสีเข้มขึ้นตามกาลเวลา โดยเฉพาะหากเก็บไว้ใกล้หน้าต่างที่โดนแสงแดดโดยตรงเป็นประจำ

ผลกระทบของกระดาษต่อประสบการณ์ผู้ใช้: การเขียน การสัมผัสจับถือ และความสบายในการมองเห็น

ความรู้สึกของกระดาษไบเบิลคือสิ่งที่ทำให้เกิดความแตกต่างเมื่อมีคนเปิดอ่านทุกวัน ผิวหยาบที่อยู่บนหน้ากระดาษแบบไม่เคลือบช่วยให้ผู้คนสามารถเขียนโน้ตด้วยดินสอหรือปากกาได้โดยหมึกไม่ซึมผ่าน นั่นจึงเป็นเหตุผลที่หลายคนชอบคุณสมบัตินี้ในพระคัมภีร์สำหรับการศึกษาของตน สีครีมอ่อนอบอุ่นของกระดาษยังช่วยให้ดวงตาสบายขณะอ่านหนังสือเป็นเวลานาน เพราะมันสะท้อนแสงน้อยกว่ากระดาษสีขาวจัด การผลิตยังทดสอบแผ่นกระดาษที่ยืดหยุ่นเหล่านี้อย่างละเอียด โดยบางครั้งนำไปผ่านการพลิกหน้าหลายพันครั้ง เพื่อให้มั่นใจว่าจะคงทนต่อการใช้งานยาวนาน และยังพลิกหน้าได้ง่าย รายละเอียดเล็กๆ เหล่านี้ทั้งหมดมีความสำคัญเมื่อต้องตัดสินใจว่าพระคัมภีร์ที่ทำด้วยมือฉบับหนึ่งจะถูกส่งต่อจากรุ่นสู่รุ่น หรือจะถูกละเลยให้กลายเป็นฝุ่นสะสมอยู่บนชั้นวางภายในไม่กี่เดือน

คุณสมบัติหลักของกระดาษพระคัมภีร์คุณภาพสูง

น้ำหนักกระดาษ (gsm) และความหนา: การถ่วงดุลระหว่างความบางและความทนทาน

กระดาษไบเบิลโดยทั่วไปจะมีน้ำหนักอยู่ระหว่าง 28 ถึง 40 กรัมต่อตารางเมตร ซึ่งบางกว่ากระดาษพิมพ์ทั่วไปที่มีความหนาประมาณ 80 แกรมต่อตารางเมตร การออกแบบนี้ถือว่าอยู่ในระดับกลางๆ ที่ดี ป้องกันไม่ให้หนังสือหนาเกินไป แต่ยังคงทนทานต่อการฉีกขาดได้ด้วยเส้นใยที่อัดแน่น เมื่อกระดาษมีความหนาน้อยกว่า 40 ไมครอน สามารถบรรจุกระดาษได้ประมาณ 1,500 หน้าภายในสันหนาเพียง 1.5 นิ้ว ซึ่งถือว่าทนทานต่อการใช้งานในชีวิตประจำวัน ผู้ผลิตส่วนใหญ่ใช้กระบวนการที่เรียกว่าการรีดกระดาษ (calendering) ซึ่งโดยพื้นฐานแล้วคือการรีดอย่างแม่นยำ เพื่อรีดเส้นใยเหล่านี้โดยไม่กระทบต่อความคมชัดของข้อความที่พิมพ์ หรือลดความสามารถในการกันแสงของกระดาษ

กระดาษปราศจากกรดและลิกนิน เพื่อคุณภาพระดับหอจดหมายเหตุและการเก็บรักษา

กระดาษไบเบิลที่ได้รับการจัดอันดับคุณภาพสำหรับการเก็บรักษาในระยะยาวนั้น ปราศจากสารลิกนินที่เป็นกรด ซึ่งเป็นตัวการทำให้กระดาษเหลืองและเปราะตามกาลเวลา กระดาษประเภทนี้มักผลิตจากวัสดุที่เป็นกลางต่อกรด เช่น ผ้าฝ้ายบริสุทธิ์ 100% หรือเยื่อไม้ที่ผ่านการบำบัดพิเศษ โดยมีค่าความเป็นกรด-ด่าง (pH) อยู่ที่ประมาณ 7 ถึง 8.5 นอกจากนี้ยังสอดคล้องกับมาตรฐาน ANSI/NISO Z39.48 สำหรับความคงทนถาวรอีกด้วย เมื่อจัดเก็บอย่างเหมาะสม วัสดุเหล่านี้สามารถคงสภาพได้นานกว่าสองร้อยปีโดยไม่เสื่อมสภาพ ถือว่าเป็นวัสดุที่น่าประทับใจมาก หอสมุดรัฐสภาสหรัฐฯ ได้ทำการทดสอบเมื่อปี 2023 และพบว่า กระดาษที่ทำจากผ้าฝ้ายยังคงความแข็งแรงไว้ได้ประมาณ 90% ของค่าเดิม แม้จะผ่านการจำลองอายุครบหนึ่งศตวรรษแล้ว นี่จึงเป็นเหตุผลที่ผู้พิมพ์จำนวนมากเลือกวัสดุเหล่านี้ในการผลิตหนังสือที่ตั้งใจให้ส่งต่อไปยังคนรุ่นหลังในฐานะสมบัติของครอบครัว

ความทึบแสงและ PPi: ลดการสะท้อนในขณะที่เพิ่มความจุของหน้าให้สูงสุด

ค่าความทึบแสง (%) และจำนวนหน้าต่อนิ้ว (PPi) มีความสัมพันธ์ผกผันกัน ซึ่งกำหนดความสามารถในการใช้งานของพระคัมภีร์:

| คุณสมบัติ | ระยะทางที่เหมาะสม | ผล |

|---|---|---|

| ระดับการบังแสง | 92%-96% | ลดการแสดงข้อความให้น้อยที่สุด |

| PPI | 800-850 | ยังคงขนาดตัวอักษรที่อ่านง่าย |

แผ่นกระดาษที่มีความทึบแสง 94% และความหนาแน่นของเส้นใย 820 PPi ช่วยเพิ่มประสิทธิภาพในการจัดวางจำนวนหน้า โดยป้องกันการเกิดเงาซ้อนที่รบกวนสายตา ซึ่งเป็นสิ่งสำคัญสำหรับพระคัมภีร์อ้างอิงขนาดกะทัดรัดที่ใช้ตัวอักษรขนาด 8 พอยต์

ประเภทกระดาษที่นิยมใช้ในการผลิตพระคัมภีร์ตามสั่ง

กระดาษพิเศษสามประเภทที่ครองตลาดการผลิตพระคัมภีร์ตามสั่ง โดยแต่ละชนิดถูกออกแบบให้สมดุลระหว่างคุณสมบัติทางกายภาพและข้อกำหนดการใช้งาน

กระดาษอินเดีย: บางมาก เหนียว และเหมาะอย่างยิ่งสำหรับพระคัมภีร์ตามสั่งขนาดกะทัดรัด

กระดาษชนิดนี้ซึ่งมีน้ำหนัก 30–40 กรัมต่อตารางเมตร ทำให้พระคัมภีร์ที่มีมากกว่า 1,500 หน้าสามารถคงความหนาเพียง 1 นิ้วได้โดยยังคงพกพาสะดวก ขณะเดียวกันก็ป้องกันหมึกซึมผ่านได้ดี เส้นใยที่เสริมด้วยโพลิเมอร์ช่วยป้องกันการฉีกขาดในขณะพลิกหน้าบ่อยๆ — เหมาะอย่างยิ่งสำหรับฉบับเผยแผ่ศาสนาและฉบับพกพาที่ใช้ในสภาพแวดล้อมที่เคลื่อนที่ตลอดเวลา

กระดาษหัวหอม: มีความโปร่งแสงสูงและแข็งแรง เหมาะสำหรับฉบับพรีเมียม

ด้วยความทึบแสง 92% และพื้นผิวย่นอันเป็นเอกลักษณ์ กระดาษ 50-60 แกรมนี้จึงสร้างสรรค์พระคัมภีร์สำหรับนำเสนอคุณภาพระดับมรดกตกทอด แผ่นกระดาษกึ่งโปร่งแสงช่วยลดการมองทะลุสำหรับตัวอักษรเรืองแสง พร้อมรองรับการประทับฟอยล์ทองและงานพิมพ์ศิลปะ ซึ่งเป็นที่ชื่นชอบสำหรับพระคัมภีร์ฉบับที่ระลึกและฉบับแต่งงาน

กระดาษแผ่นหลวมและกระดาษผสม: ทางเลือกที่คุ้มค่าด้วยประสิทธิภาพที่เชื่อถือได้

มีต้นทุนต่ำกว่ากระดาษพิเศษ 40% (ตามเกณฑ์มาตรฐานอุตสาหกรรมการพิมพ์ ปี 2024) กระดาษชนิดนี้หนา 70–80 กรัม/ตารางเมตร ผลิตจากการผสมเยื่อไม้กับเส้นใยฝ้าย เหมาะสำหรับคำสั่งซื้อจำนวนมากของคริสตจักร พื้นผิวหยาบปานกลางรองรับทั้งการพิมพ์รายชื่อด้วยเครื่องเลเซอร์และการเขียนโน้ตด้วยดินสอ ทำให้เหมาะสมกับการใช้งานในพระคัมภีร์สำหรับกลุ่มเยาวชนและกลุ่มศึกษาพระคัมภีร์

ผู้ผลิตมักเลือกใช้กระดาษผสมเมื่อผลิตพระคัมภีร์ตามสั่งที่ต้องการความทนทานสำหรับการใช้งานประจำวันโดยไม่ต้องตั้งราคาพรีเมียม ในขณะที่จะเก็บกระดาษอินเดียและกระดาษอนิออนสกินไว้สำหรับการใช้งานพิเศษที่เน้นความสะดวกในการพกพาหรือผลกระทบด้านรูปลักษณ์เป็นหลัก

กระดาษเคลือบ vs. ไม่เคลือบ และ สี vs. พื้นผิว: การเลือกกระดาษให้เหมาะกับการใช้งาน

กระดาษไม่เคลือบสำหรับการเขียนและจดบันทึก เทียบกับกระดาษเคลือบเพื่อความชัดเจนในการออกแบบ

พื้นผิวด้านของกระดาษไม่เคลือบเหมาะมากสำหรับพระคัมภีร์แบบปรับแต่งที่ผู้คนต้องการใช้จดบันทึก เพราะหมึกจะซึมลงบนกระดาษได้ดีโดยไม่กระจายออก ทำให้ข้อความที่เขียนด้วยมือยังคงคมชัดและอ่านง่าย แม้จะใช้ปากกาหมึกซึมแบบหรูหรา กับพระคัมภีร์ศึกษาที่ภาพสีและแผนที่มีความสำคัญมาก กระดาษเคลือบจะช่วยให้ภาพเหล่านั้นเด่นชัดขึ้นเมื่อเทียบกับพื้นหลัง นอกจากนี้ การศึกษาล่าสุดในปี 2024 ยังพบสิ่งที่น่าสนใจอีกด้วย คือ กระดาษที่เคลือบผิวมีอายุการใช้งานนานกว่ากระดาษธรรมดาประมาณ 30 เปอร์เซ็นต์ จึงเข้าใจได้ว่าทำไมสำนักพิมพ์จึงใส่ใจเป็นพิเศษในการเคลือบหน้ากระดาษสำหรับเวอร์ชันที่เน้นการอ้างอิง ซึ่งมักถูกเปิดใช้งานซ้ำแล้วซ้ำอีกตลอดเวลา

กระดาษสีครีม vs. ขาว: การลดแสงสะท้อนและเพิ่มความสบายในการอ่าน

โทนสีครีมช่วยลดความเมื่อยล้าของดวงตาเมื่ออ่านหนังสือเป็นเวลานาน เนื่องจากมีแสงสะท้อนโดยรวมน้อยลง จึงเป็นเหตุผลว่าทำไมหลายคนจึงชอบใช้กระดาษสีครีมสำหรับข้อความทางศาสนาของตน แม้ว่าหน้ากระดาษสีขาวธรรมดาจะทำให้ตัวอักษรเด่นชัดกว่าพื้นหลัง แต่ก็สะท้อนแสงกลับมากเกินไป ซึ่งมักจะทำให้ดวงตาล้าหลังจากใช้งานไปสักพัก ตามสถิติในอุตสาหกรรมจากรายงานอุตสาหกรรมการพิมพ์ปีที่แล้ว หนังสือคุณภาพสูงประมาณเจ็ดในสิบเล่มผลิตบนกระดาษสีครีม ผู้จัดพิมพ์ดูเหมือนจะเข้าใจแล้วว่าผู้อ่านต้องการสิ่งที่ทั้งสวยงามทางสายตาและสบายต่อการมองดูในช่วงเวลาอ่านหนังสือต่อเนื่องยาวนาน

ผิวด้าน, ผิวไข่, และผิวเรียบ: การสัมผัสเชิงสัมผัสและการใช้งานที่เหมาะสม

- ผิวด้าน ลดการสะท้อนแสงขณะคงความทึบเพื่อการพิมพ์สองด้าน

- ผิวแบบไข่ (Eggshell finishes) ให้พื้นผิวสัมผัสเบาๆ เพื่อให้พลิกหน้าได้ง่าย โดยไม่ระคายเคือง

- ผิวเรียบ (Smooth finishes) เพิ่มประสิทธิภาพการอ่านสำหรับพระคัมภีร์ขนาดกะทัดรัดที่มีข้อความแน่น

พื้นผิวเหล่านี้ช่วยสร้างความสมดุลระหว่างความชอบเชิงสัมผัสกับความต้องการใช้งานจริง—แบบด้านสำหรับการอ่านในที่แสงน้อย แบบไข่เป็ดเพื่อการสัมผัสที่ดี และแบบเรียบสำหรับรุ่นที่พกพาได้โดยต้องการขนาดที่บางเฉียบ

การเลือกกระดาษที่เหมาะสมสำหรับการใช้งานไบเบิลแบบปรับแต่งเฉพาะทาง

ไบเบิลสำหรับพระสงฆ์และนักเทศน์: ความทนทานและความต้องการต่ำในการสะท้อนแสง

บาทหลวงและผู้นำคริสตจักรต้องการกระดาษที่ทนทานต่อการใช้งานหนักระหว่างการนมัสการและเทศนา ด้วยเหตุนี้ คนส่วนใหญ่จึงพบว่ากระดาษที่มีน้ำหนักประมาณ 60 ถึง 70 กรัมต่อตารางเมตรจะใช้งานได้ดีที่สุดเมื่อปราศจากกรดและมีผิวด้าน พื้นผิวด้านช่วยลดแสงสะท้อนที่น่ารำคาญเมื่ออ่านใต้แสงไฟในโบสถ์ อีกทั้งยังทนทานต่อการฉีกขาดโดยไม่ได้ตั้งใจ จากงานวิจัยล่าสุดที่ตีพิมพ์ใน Religious Text Study (2023) พบว่าสมาชิกคริสตจักรประมาณแปดในสิบคนให้ความสำคัญกับความทึบของกระดาษ โดยเลือกใช้กระดาษที่มีความหนาอย่างน้อย 96 PPi เพื่อป้องกันไม่ให้หมึกซึมออกมาเมื่อเน้นข้อความในส่วนสำคัญ เรื่องนี้สำคัญมากเพราะไม่มีใครอยากให้บันทึกของพวกเขาปรากฏทะลุผ่านหน้ากระดาษระหว่างการนมัสการ

พระคัมภีร์สำหรับอ่านประจำวันและการเขียนบันทึก: กระดาษที่เหมาะสมที่สุดสำหรับการจดบันทึก

การมีส่วนร่วมกับพระคัมภีร์แบบอินเตอร์แอคทีฟต้องอาศัยกระดาษที่สมดุลระหว่างพื้นผิวที่เขียนลื่นไหลกับความต้านทานการซึมของหมึก กระดาษแผ่นหลวมที่มีเนื้อผ้าฝ้าย 5–7% มีการเลอะของหมึกน้อยกว่ากระดาษทั่วไปถึง 40% (Stationery Analytics 2024) ตัวเลือกกระดาษโทนครีมหนา 80 กรัม/ตารางเมตร ช่วยลดอาการเมื่อยล้าของสายตาในช่วงเวลาที่ใช้งานต่อเนื่อง โดยผู้ใช้งาน 60% รายงานว่าสามารถจดจ่อกับงานได้ดีขึ้นในสภาพแสงสลัว

ฉบับของขวัญและที่ระลึก: กระดาษคุณภาพเก็บรักษาเพื่อมูลค่าที่คงทน

พระคัมภีร์สำหรับสืบทอดต้องใช้กระดาษปราศจากลิกนินที่เป็นไปตามมาตรฐานการเก็บรักษาระดับ ISO 9706 ซึ่งสามารถคงสภาพได้มากกว่า 100 ปีโดยไม่เหลือง ผู้ผลิตชั้นนำใช้กระดาษหนา 45 กรัม/ตารางเมตรที่เป็นกลางทาง pH และเคลือบด้วยสารกันกรดอัลคาไลน์ เพื่อรักษาขอบทองคำเปลวและปกปั๊มฟอยล์ให้คงอยู่ตลอดหลายชั่วอายุคน กระดาษเหล่านี้มีความต้านทานการเปลี่ยนแปลงของความชื้นในสิ่งแวดล้อมได้สูงถึง 99.9% (Conservation Materials Report 2024)

ด้วยการปรับคุณสมบัติของกระดาษให้สอดคล้องกับสถานการณ์การใช้งาน ผู้ผลิตพระคัมภีร์แบบเฉพาะตัวจึงสามารถมั่นใจได้ว่าแต่ละฉบับจะทำหน้าที่ทางจิตวิญญาณและความใช้สอยได้อย่างมีคุณภาพที่คงทนยาวนาน

คำถามที่พบบ่อย

ทำไมการเลือกกระดาษถึงมีความสำคัญในการออกแบบพระคัมภีร์ตามสั่ง

การเลือกกระดาษมีผลโดยตรงต่อการอ่านได้ชัดเจน ความทนทาน และการใช้งานของพระคัมภีร์ มันช่วยให้มั่นใจว่าข้อความไม่ซึมผ่านกระดาษ ทนต่อการสัมผัสบ่อยครั้ง และเพิ่มความสะดวกสบายในการอ่าน

ความหนาของกระดาษที่แนะนำสำหรับพระคัมภีร์คือเท่าใด

น้ำหนักกระดาษที่เหมาะสมสำหรับพระคัมภีร์ควรอยู่ในช่วง 28 ถึง 40 กรัมต่อตารางเมตร เพื่อให้สมดุลระหว่างความบางและความทนทาน พร้อมทั้งคงความสามารถในการพกพา

ทำไมกระดาษพระคัมภีร์ควรเป็นชนิดปราศจากกรด

กระดาษปราศจากกรดช่วยป้องกันไม่ให้หน้ากระดาษพระคัมภีร์เปราะและเหลืองตามกาลเวลา ทำให้มั่นใจถึงอายุการใช้งานของข้อความ โดยเฉพาะในสภาพแวดล้อมที่มีความชื้นสูง

การใช้กระดาษสีครีมสำหรับพระคัมภีร์มีข้อดีอย่างไร

กระดาษสีครีมช่วยลดแสงสะท้อน ทำให้การอ่านสะดวกสบายมากขึ้นในช่วงเวลานาน โดยลดอาการเมื่อยล้าของดวงตา

กระดาษประเภทใดที่เหมาะที่สุดสำหรับพระคัมภีร์ที่สืบทอดเป็นมรดก

กระดาษที่ปราศจากไลก์นินและมีค่า pH เป็นกลาง ซึ่งเป็นไปตามมาตรฐานการเก็บรักษายาวนาน เหมาะสมที่สุดสำหรับพระคัมภีร์มรดก เพราะสามารถคงสภาพได้มากกว่าหนึ่งศตวรรษโดยไม่เสื่อมสภาพ

สารบัญ

- เหตุใดการเลือกกระดาษจึงสำคัญต่อการออกแบบพระคัมภีร์แบบปรับแต่ง

- คุณสมบัติหลักของกระดาษพระคัมภีร์คุณภาพสูง

- ประเภทกระดาษที่นิยมใช้ในการผลิตพระคัมภีร์ตามสั่ง

- กระดาษเคลือบ vs. ไม่เคลือบ และ สี vs. พื้นผิว: การเลือกกระดาษให้เหมาะกับการใช้งาน

- การเลือกกระดาษที่เหมาะสมสำหรับการใช้งานไบเบิลแบบปรับแต่งเฉพาะทาง

- คำถามที่พบบ่อย