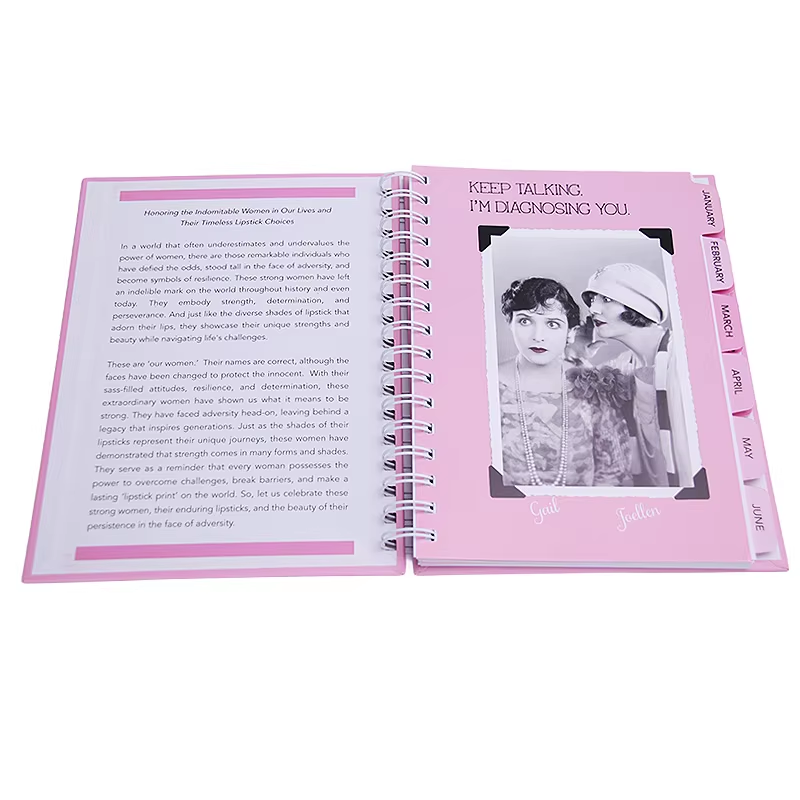

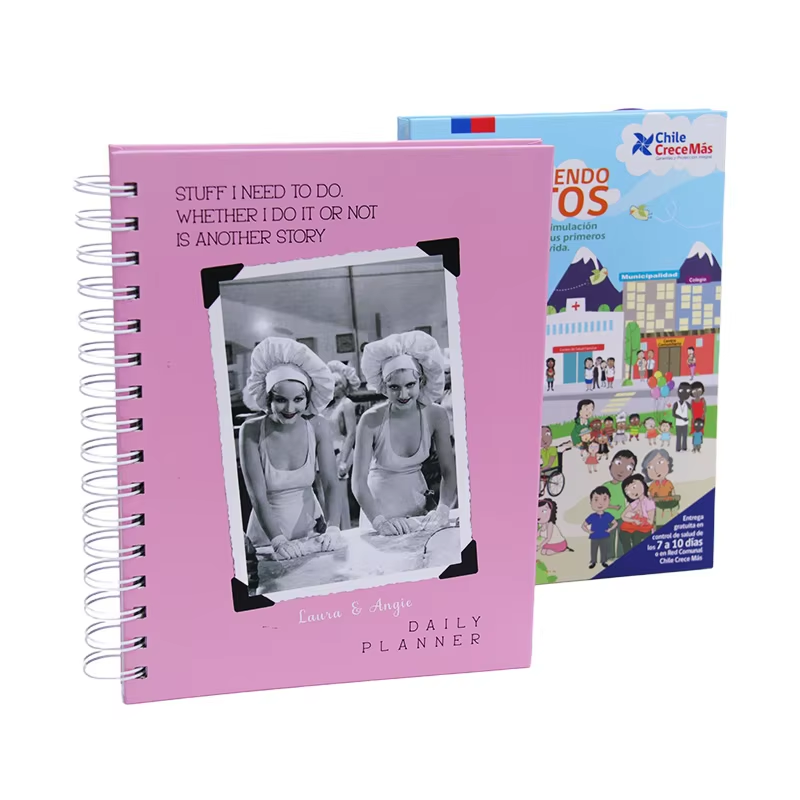

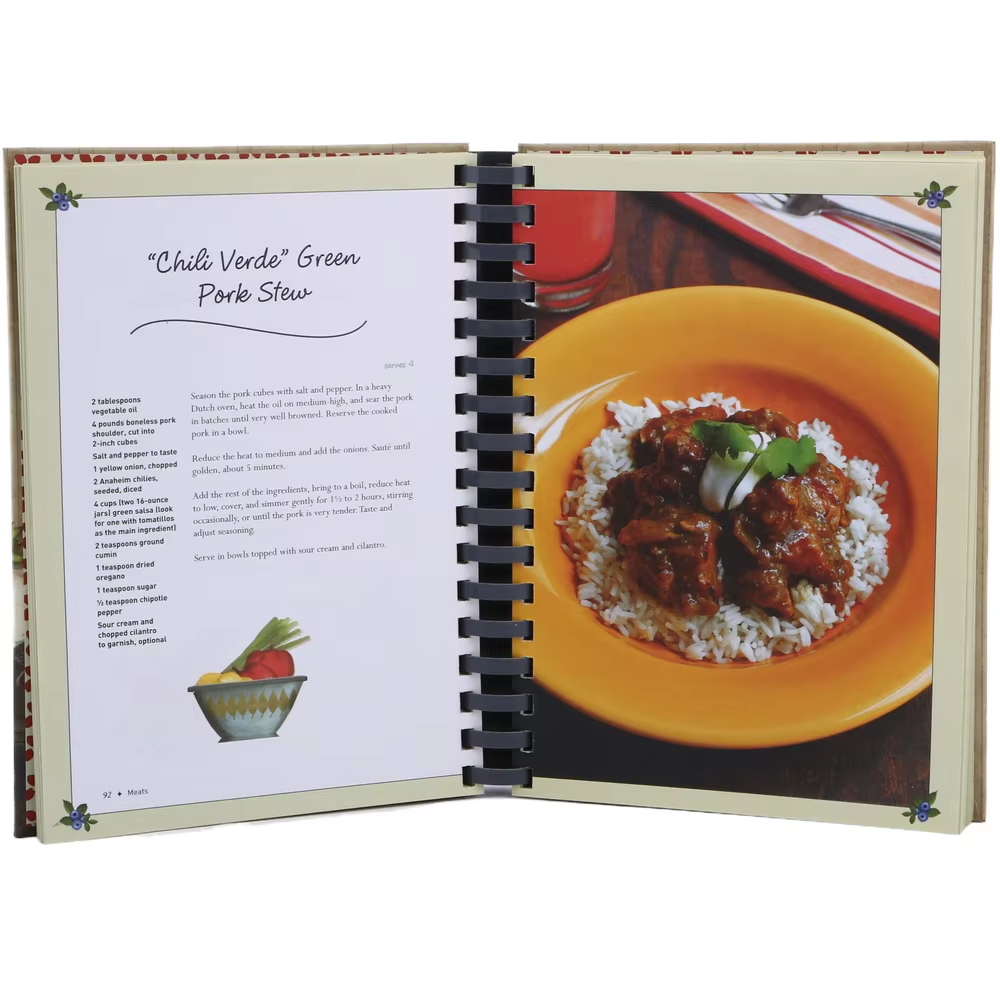

The company, with decades of experience since 2000, employs advanced spiral binding techniques to create durable, functional printed products for a variety of applications. Spiral binding techniques involve inserting a continuous coil—made of metal or plastic—through evenly spaced holes along the edge of stacked pages, securing them together while allowing the pages to rotate 360 degrees and lie flat when open. These spiral binding techniques are versatile, suitable for notebooks, calendars, catalogs, and workbooks, with the coil’s flexibility accommodating varying page counts from a few sheets to hundreds of pages. The company’s spiral binding techniques include precision hole punching to ensure the coil threads smoothly, and options for coil crimping at the ends to prevent uncoiling, enhancing the product’s durability. Spiral binding techniques can be customized with different coil colors, diameters, and materials (such as rust-resistant metal for long-term use or lightweight plastic for cost-effectiveness), allowing the binding to complement the product’s design. Leveraging Shenzhen’s industrial expertise, the company’s spiral binding techniques are executed with efficiency and consistency, ensuring high-quality results for orders of all sizes, exported to over 50 countries. Whether for functional or promotional products, spiral binding techniques from this manufacturer combine practicality with reliability.